HEBEI DELIN MACHINERY CO.,LTD

.jpg)

| Type | Capacity(Q) | Head(H) | Speed(n) | Max. Eff. | NPSH | Suction Dia. | Discharge Dia. | Max. Particle Size Allowed | Weight | |

| (m³/h) | (l/s) | (m) | (r/min) | (%) | (m) | (mm) | (mm) | (mm) | (kg) | |

| DG150X100-D | 36~252 | 10~70 | 3.5~51 | 600~1400 | 30~50 | 2.5~3.5 | 150 | 100 | 82 | 460 |

| DG200X150-E | 137~576 | 38~160 | 10~48 | 800~1400 | 50~60 | 3~4.5 | 200 | 150 | 127 | 1120 |

| DG250X200-S | 216~979 | 60~272 | 13~50 | 500~1000 | 45~65 | 3~7.5 | 250 | 200 | 178 | 2285 |

| DG300X250-G | 360~1512 | 100~420 | 11~58 | 400~850 | 50~70 | 2~4.5 | 300 | 250 | 220 | 4450 |

| DG350X300-G | 504~3168 | 140~880 | 6~66 | 300~700 | 60~68 | 2~8 | 350 | 300 | 240 | 5400 |

| DG450X400-T | 864~3816 | 240~1060 | 9~48 | 250~500 | 60~72 | 3~6 | 450 | 400 | 254 | 10800 |

| DG250X200H-S | 396~1296 | 110~360 | 10~80 | 500~950 | 60~72 | 2~5 | 250 | 200 | 180 | 3188 |

| DG300X400H-T | 612~2232 | 170~620 | 28~78 | 350~700 | 60~72 | 2~8 | 300 | 250 | 210 | 4638 |

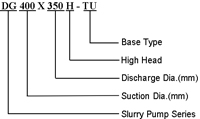

| DG400X350H-TU | 720~3600 | 200~1000 | 20~72 | 300~500 | 60~72 | 3~6 | 400 | 350 | 230 | 12250 |

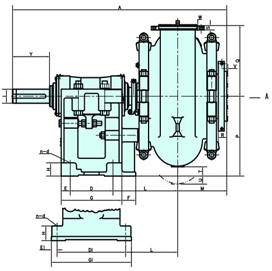

| Modal | Outline Dimension | ||||||||||||||||

| A | B | C | D | E | F | G | D1 | E1 | G1 | H | Y | I | N-d | L | M | N | |

| DG150X100-D | 1006 | 492 | 432 | 213 | 38 | 75 | 289 | - | - | - | 54 | 164 | 65 | 4-Ф22 | 330 | 203 | 260 |

| DG200X150-E | 1286 | 622 | 546 | 257 | 54 | 83 | 365 | - | - | - | 75 | 222 | 80 | 4-Ф29 | 392 | 295 | 352 |

| DG250X200-S | 1720 | 920 | 760 | - | - | - | - | 640 | 70 | 780 | 90 | 280 | 120 | 4-Ф35 | 378 | 330 | 416 |

| DG300X250-G | 2010 | 1207 | 851 | - | - | - | - | 749 | 64 | 876 | 152 | 356 | 140 | 4-Ф41 | 473 | 368 | 522 |

| DG350X300-G | 2096 | 1207 | 851 | - | - | - | - | 749 | 64 | 876 | 152 | 356 | 140 | 4-Ф41 | 502 | 424 | 610 |

| DG450X400-T | 2320 | 1150 | 900 | - | - | - | - | 880 | 80 | 1040 | 125 | 350 | 150 | 4-Ф48 | 538 | 439 | 692 |

| DG250X200H-S | 1774 | 920 | 760 | - | - | - | - | 640 | 70 | 780 | 90 | 280 | 120 | 4-Ф35 | 455 | 330 | 475 |

| DG300X400H-T | 2062 | 1219 | 851 | - | - | - | - | 749 | 64 | 876 | 152 | 356 | 140 | 4-Ф41 | 496 | 400 | 605 |

| DG400X350H-TU | 2367 | 1460 | 1200 | - | - | - | - | 860 | 95 | 1050 | 150 | 350 | 150 | 4-Ф70 | 649 | 448 | 765 |

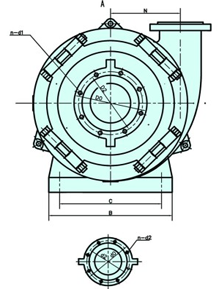

| Modal | Outline Dimension | Intake Flange Dimension | Outlet Flange Dimension | Weight | |||||||||||

| P | Q | R | S | T | U | V | W | D0 | D2 | n-d1 | n0 | n2 | n-d2 | ||

| DG150X100-D | 330 | 343 | 33 | 32 | 16 | - | 8 | 5 | 305 | 260 | 8-Ф19 | 254 | 210 | 4-Ф19 | 460 |

| DG200X150-E | 457 | 405 | 29 | 29 | 54 | - | 6 | 8 | 368 | 324 | 8-Ф19 | 305 | 260 | 8-Ф19 | 1120 |

| DG250X200-S | 450 | 533 | 48 | 41 | - | 102 | 8 | 6 | 457 | 406 | 8-Ф22 | 368 | 324 | 8-Ф19 | 2285 |

| DG300X250-G | 851 | 665 | 48 | 49 | 238 | - | 10 | 8 | 527 | 470 | 12-Ф22 | 457 | 406 | 8-Ф22 | 4450 |

| DG350X300-G | 851 | 787 | 48 | 48 | 121 | - | 8 | 10 | 552 | 495 | 8-Ф22 | 527 | 470 | 12-Ф22 | 5400 |

| DG450X400-T | 650 | 921 | 64 | 64 | - | 274 | 8 | 10 | 705 | 641 | 16-Ф25 | 640 | 584 | 12-Ф25 | 10800 |

| DG250X200H-S | 450 | 620 | 48 | 42 | - | 206 | 8 | 6 | 457 | 406 | 8-Ф22 | 368 | 324 | 8-Ф19 | 3188 |

| DG300X400H-T | 851 | 800 | 60 | 60 | 40 | - | 10 | 8 | 533 | 476 | 8-Ф29 | 483 | 432 | 8-Ф25 | 4638 |

| DG400X350H-TU | 900 | 1008 | 72 | 82 | - | 120 | 8 | 10 | 650 | 600 | 12-Ф28 | 600 | 540 | 12-Ф28 | 12247 |

Tag: Heavy-duty sewage pump | Heavy duty suction pump double | Heavy duty pump for supplying gravel | Heavy duty pump for radioactive liquids

Tag: Pumping unit for the coal industry | Pumping unit for FGD | Pumping unit flue gas desulfurization | Pumping unit for desulfurization